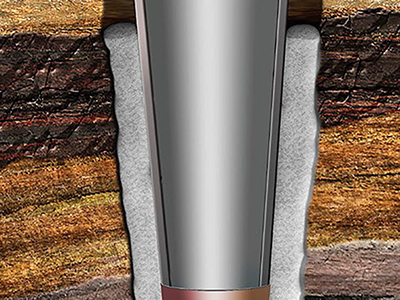

Cementing

Gilsonite is a Critical Component For Cementing

Cementing

As the oil-producing industry has continued to grow, the need for a low-density cementing slurry possessing lost-circulation control characteristics has become more and more evident. This is especially so In primary cementing because of the different types of formations being encountered and the need to reduce remedial cementing operation These problem formations may range from either porous or cavernous formations to very weak formations that are unable to support the hydrostatic head that is necessary for drilling and well completion. This latter type of formation will often break down or fracture under hydrostatic loading, resulting in partial or complete loss of circulation.

Lost-circulation zones encountered during drilling operation may produce many problems In the normal course of completing a well. Increased expenditures can result from reduced drilling finishing jobs, and other mechanical difficulties as well as from loss of large volumes of drilling fluid . Sometimes severe lost-circulation problems may even cause abandonment of a well. Lost circulation during cementing operations will often be reflected by inadequate fill-up In the annulus and the consequent displacement of slurry into formations away from the well bore. Satisfactory isolation of the different formations may then require re-cementing work above the point of loss and subsequent squeeze-cementing jobs. Lost circulation while cementing , although there is some overlapping In areas where cementing slurries with excellent bridging properties may be used advantageously to rest.ore mud circulation.

Attempts have been made to restore circulation while cementing using many types of materials Sometimes sufficiently good results have been obtained simply by reducing the slurry density whereas other instances have occurred where bridging materials were found to be most helpful but there still remained zones of loss which would not react satisfactorily to either of these methods. Combinations of these two approaches have also been utilized.

In the formulation of the cementing composition of the invention, it is preferable to employ Gilsonite in an amount ranging from approximately one-half to approximately ten times by volume the amount of the cement utilized, depending upon the particular result desired.

The lower range is employed where maximum strength is important; the higher range where the various qualities imparted by the Gilsonite are most important.

Particle size and particle size distribution of the Gilsonite determine the strength and porosity-permeability characteristics of the set cement for any given mix ratio.

Where maximum strength is desirable, a coarse Gilsonite Where lightest weight and lowest porosity-permeability are important and strength is to be sacrificed or is of little importance, an aggregate of minus 50 mesh or finer may be used.

Benefits

• When perforated, it is shatter-resistant.

• It does not significantly affect the setting time of cement.

• Gilsonite additive can provide higher strength than heavier additives with high water requirements.

Gilsonite additive is effective at Bottom Hole Temperatures (BHTs) between 60° and 230°F (16° and 110°C). Typical additive concentrations range from 5 to 50 lb/ski of cement.

Gilsonite additive’s low specific gravity helps improve its ability to control lost circulation. However, this feature can also cause the additive to separate to the top of thin slurries and slurries containing dispersants.